Flow meters are critical instruments used to measure the flow rate, volume, or mass of fluids in industrial, municipal, and commercial systems. With the increasing demand for automation, accuracy, and energy efficiency, modern flow meters must operate reliably across a wide range of conditions — from clean water to corrosive chemicals, high-viscosity fluids, steam, gases, and slurry.

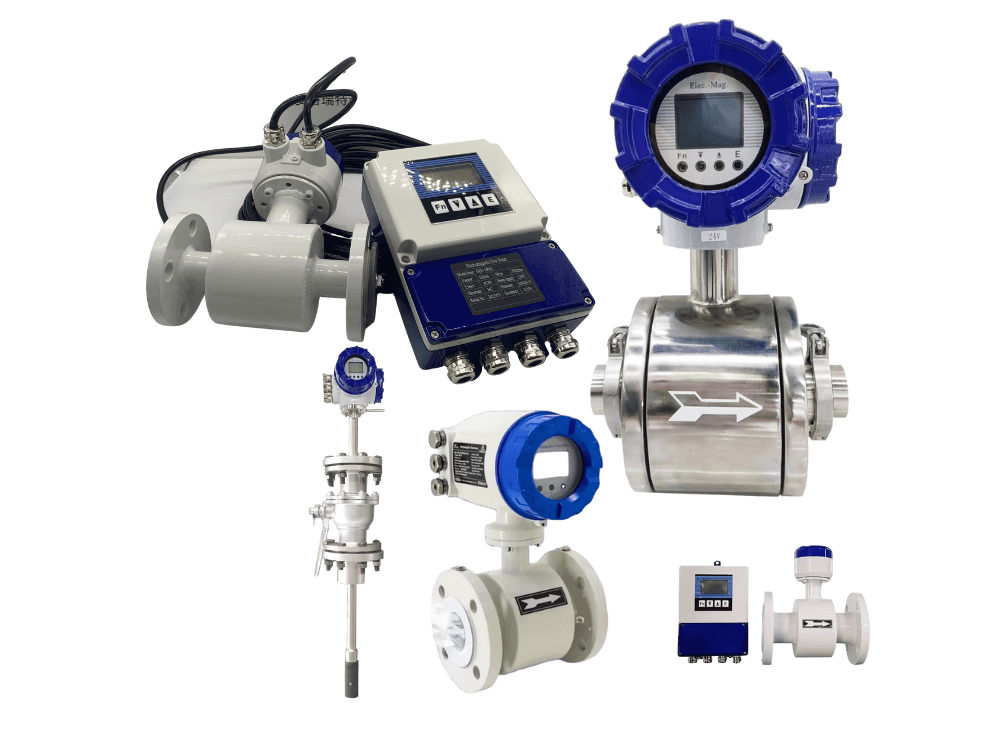

The flow meters in this collection — Coriolis, Electromagnetic, Gas Turbine, Liquid Turbine, and Vortex — represent a complete portfolio suitable for nearly every flow-measurement requirement. These instruments offer high precision, digital communication, explosion-proof options, IP67/IP68 protection, and advanced electronics to ensure accurate and stable performance even in harsh environments.

From water treatment and chemical processing to steam measurement and gas metering, these flow meters integrate seamlessly with PLCs, HMIs, DCS, and IoT monitoring systems to support automated control and operational optimization.

What is a Flow Meter?

A flow meter is a device that measures the flow rate of a fluid (liquid, gas, or steam) as it moves through a pipe. Different technologies are used depending on the type of fluid, accuracy required, and process conditions.

1. Coriolis Mass Flow Meter (GCF-1000 Series)

Measures mass flow directly using the Coriolis force principle.

Also provides density, temperature, concentration, and volume flow simultaneously.

Key technologies include:

DSP closed-loop processing

Self-adaptive drive circuits

Multi-parameter measurement

Ultra-stable zero point

Tube geometries: U-type, V-type, S-type, Triangle-type

2. Electromagnetic Flow Meter (GEF-1000 Series)

Ideal for conductive liquids (>20 μS/cm).

Uses Faraday’s Law of Electromagnetic Induction.

Has no moving parts and provides extremely stable, drift-free measurement.

Features include:

PTFE lining >3mm

Pure copper coils (99.999%)

IP68 waterproofing

Bi-directional measurement

Excellent small-flow performance (down to 0.01 m³/h)

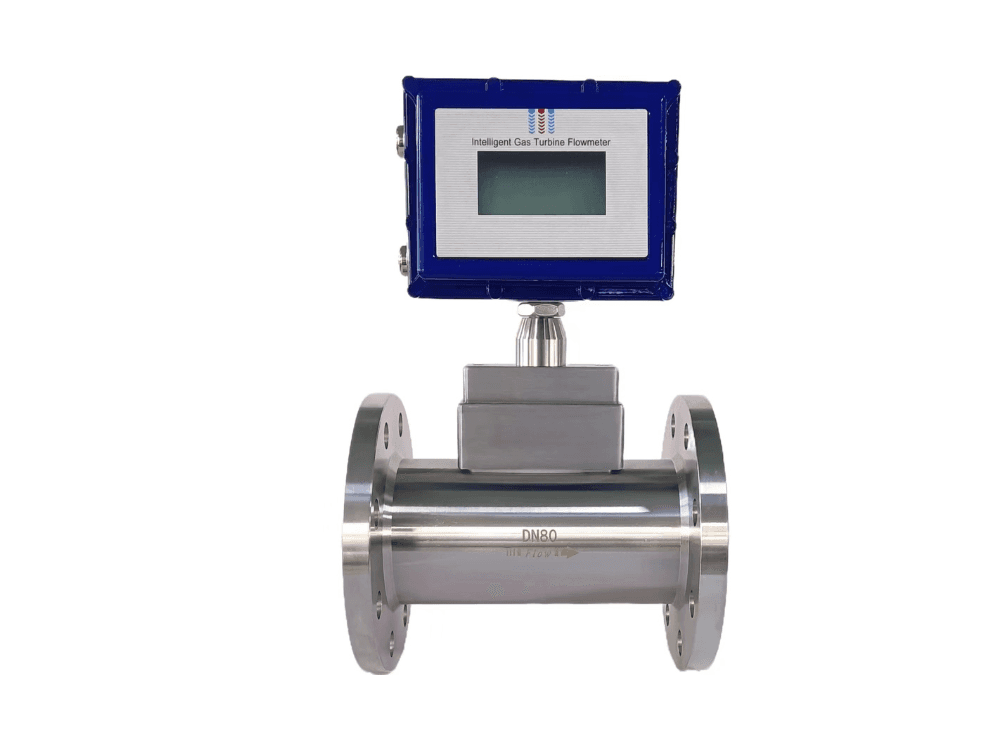

3. Gas Turbine Flow Meter

Uses a high-speed turbine rotor whose speed is proportional to gas flow.

Suitable for air, nitrogen, natural gas, and compressed gases.

Offers wide ranges up to 650–13,000 m³/h depending on pipe size.

4. Liquid Turbine Flow Meter (GTF-1000L Series)

Ideal for clean, low-viscosity liquids.

Provides high accuracy (up to ±0.2%) and fast response.

Available in threaded, flange, and sanitary connections.

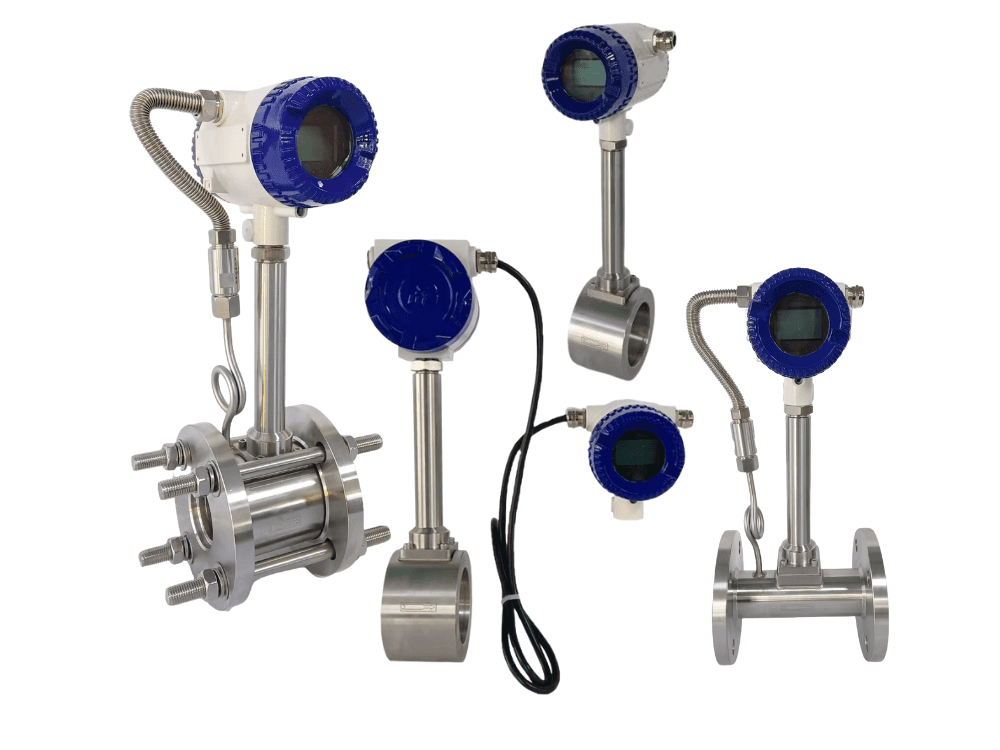

5. Vortex Flow Meter (GVF-1000 Series)

Measures liquids, gases, and steam using the vortex shedding principle.

Highly suitable for saturated steam, compressed air, and industrial gases.

Available in wafer and flange types with remote or integrated electronics.

Specifications

Measurement, Media, Accuracy, Temp, Pressure

Category | Coriolis Mass Flow Meter | Electromagnetic Flow Meter | Gas Turbine Flow Meter |

|---|---|---|---|

Measurement Principle | Coriolis force (direct mass flow) | Faraday’s Law (conductive liquids) | Rotor rotation + velocity |

Media Type | Liquids, gases, steam, slurry, viscous fluids | Conductive liquids >20 μS/cm | Air, nitrogen, clean gases |

Accuracy | ±0.1% to ±0.5% | High accuracy for liquids | Medium–high |

Temperature Range | −273°C to 450°C | Normal to high temp (PTFE liner) | Standard gas temps |

Pressure Rating | Up to 100 MPa | Up to PN16/PN25/PN40 | Typical pipeline pressures |

Category | Liquid Turbine Flow Meter | Vortex Flow Meter | Selection Note |

|---|---|---|---|

Measurement Principle | Rotor rotation (clean liquids) | Vortex shedding (Kármán vortices) | Choose by media: liquids (turbine) vs steam/gas (vortex). |

Media Type | Clean low-viscosity liquids | Steam, gas, liquids | Turbine for clean liquids; vortex for steam/air/gas lines. |

Accuracy | ±0.2%–1% | Medium for steam/gas | Turbine used when higher liquid accuracy is needed. |

Temperature Range | −20°C to 150°C | High-temperature steam/gas | Vortex suits hotter lines (steam headers). |

Pressure Rating | Depends on body/flange | PN16–PN40 | Both available in standard industrial ratings |

Output Signals + Installation

Category | Coriolis Mass Flow Meter | Electromagnetic Flow Meter | Gas Turbine Flow Meter |

|---|---|---|---|

Output Signals | 4–20 mA, Pulse, Modbus, HART, Profibus, FF | 4–20 mA, Pulse, RS485 | Pulse / 4–20 mA |

Installation | Inline (U, V, S, Triangle tubes) | Flange, insertion, sanitary | Flange or threaded |

Strengths & Applications

Category | Liquid Turbine Flow Meter | Vortex Flow Meter | Selection Notes |

|---|---|---|---|

Key Strengths | High accuracy for clean liquids | Steam & gas specialist; robust | Choose based on medium (liquid vs steam/gas) |

Typical Applications | Fuel, water, batching | Steam boilers, compressed air | Use Vortex for high-temp utilities |

Conclusion

This complete family of flow meters — Coriolis, Electromagnetic, Gas Turbine, Liquid Turbine, and Vortex — offers comprehensive coverage for nearly every industrial fluid measurement requirement. These instruments deliver high accuracy, wide measurement ranges, robust construction, and advanced digital communication options.

With multi-parameter measurement, explosion-proof designs, high-temperature and high-pressure tolerance, and compatibility with PLC, SCADA, IoT, and APS control systems, these flow meters form a powerful foundation for modern automated process control.

They can reliably measure gases, liquids, steam, slurries, and complex multi-phase fluids across industries such as water treatment, oil & gas, chemical processing, food & beverage, mining, HVAC, and manufacturing.