Level sensors are essential instruments used to monitor, measure, and control the height or depth of liquids (and in some cases solids) in tanks, wells, reservoirs, industrial vessels, and open channels. They support automation, prevent overflows, ensure reliable pump operation, and maintain process stability in critical applications such as water treatment, oil & gas, manufacturing, chemical processing, and agricultural systems.

Modern level sensors come in multiple technologies — hydrostatic submersible probes, ultrasonic non-contact transmitters, and wireless 4G-connected level detectors — each designed to suit different environmental and operational needs. These devices deliver continuous, accurate, and real-time level data to PLCs, HMIs, SCADA, IoT dashboards, and cloud platforms, enabling fully automated monitoring.

The level sensors you provided include robust stainless-steel submersible transmitters, high-precision ultrasonic units, digital display models, and low-power wireless telemetry systems, forming a complete solution for industrial and municipal water management.

What is a Level Sensor?

A level sensor is an electronic device that measures the height of a liquid (or solid) inside a container and converts it into an electrical signal for use in control systems.

Include two main technologies:

1. Hydrostatic Level Sensors (GLT-1000L / GLT-1000LD / GLT-1000LW)

Measure level using liquid pressure at the bottom of the tank:

Level = Pressure / (Density × g)

Characteristics:

Submersible stainless-steel probe

Diffused-silicon or MEMS pressure sensor

High stability and accuracy

Cable-vented for automatic barometric compensation

Deep-range capability (up to 200 m)

Variants include:

GLT-1000L: Industrial submersible probe (0–200 m)

GLT-1000LD: Same probe + digital display on housing

GLT-1000LW:4G wireless telemetry, cloud platform, Bluetooth configuration

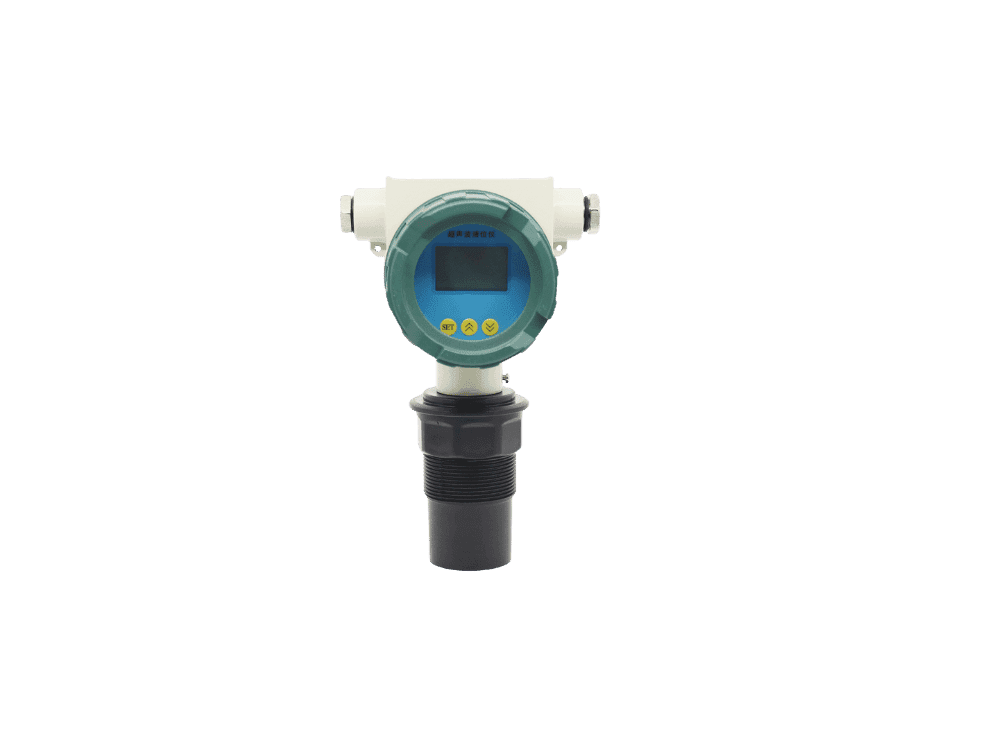

2. Ultrasonic Level Sensors (GUL-1000H / GUL-1000 Series)

Non-contact level measurement using ultrasonic pulses.

Probe emits ultrasonic waves

Echo return time = distance

Corrected using built-in temperature compensation

No contact with liquid → low maintenance

Suitable for corrosive or dirty liquids

Ranges:

0–15 m (GUL-1000H)

Up to 0–50 m (GUL-1000 Series)

Outputs:

4–20 mA

RS232

RS485

Relay

Together, these level sensors cover submersible, non-contact, digital, and wireless industrial level-measurement needs.

Specifications

🟩 TABLE A — Device Type • Model • Sensor Technology

Device Type | Model | Sensor Technology |

|---|---|---|

General Pressure Transmitter | GPT-1000 | Diffusion silicon |

General Pressure Transmitter w/ Display | GPT-1000D | Diffusion silicon |

Smart Monocrystalline Pressure Transmitter | GPT-1000DMS | Monocrystalline silicon |

High-Precision Digital Pressure Gauge | GPG-1000HV | High-precision digital pressure module |

🟦 TABLE B — Range • Accuracy • Outputs

Range | Accuracy | Outputs |

|---|---|---|

-0.1–100 MPa | 0.5% / 0.25% | 4–20 mA / RS485 / 0–10 V |

-0.1–100 MPa | 0.5% / 0.25% | 4–20 mA / RS485 / HART |

Differential 0–0.125 kPa → 7 MPa; Gauge 0–42 MPa | 0.075% F.S | 4–20 mA + HART / RS485 |

-0.1–60 MPa | 0.05% / 0.02% F.S | Local digital display + voltage/current measurement |

🟪 TABLE C — Key Features • Protection

Key Features | Protection |

|---|---|

High stability, shock-resistant, SS304/316 | IP65, Ex ia IIB T6 |

LCD/LED display, flange options, multi-connection | IP65, Ex-proof |

100:1 turndown, damping 0–30 s, self-diagnostics, multi-unit LCD | Explosion-proof, waterproof |

Portable, calibration tool, multi-sensor support, alarms | Silicone-protected housing, rugged design |

Conclusion

Level sensors are essential for accurate and reliable control of water, wastewater, chemical solutions, fuels, and industrial liquids. The combination of hydrostatic and ultrasonic technologies in your product range provides a complete solution capable of serving deep wells, corrosive ponds, tanks, reservoirs, industrial processes, and remote monitoring applications.

The GLT-1000 L-series transmitters offer rugged, high-accuracy submersible measurement with optional display and cloud-connected wireless communication, while the GUL-1000 ultrasonic series provides a reliable, non-contact solution ideal for corrosive or dirty environments.

With high accuracy, digital outputs, wireless telemetry, advanced diagnostics, and IP67/IP68 protection, these level sensors integrate seamlessly into APS Technology’s PLC, HMI, SCADA, and IoT-based automation systems.